What do successful warehouse managers and fulfilment teams have in common? They understand the power of efficient warehouse picking stations. Organising your storage bins and racking isn't just about tidiness – it’s a strategy that improves picking speed, enhances safety and streamlines inventory control.

Want to learn more? In this guide, we explain what makes a good picking station and how to introduce one into your workplace.

What makes a good warehouse picking station?

Want to boost warehouse efficiency? The first step is researching the ingredients of a successful picking station. Luckily, it's not complicated – simply focus on the following key principles.

Accessibility of items

Storage bins for picking should always be within easy reach to minimise unnecessary strain, which means no jumping, climbing or pulling. Companies should always prioritise employee safety. When unsure, contact your health and safety representative or consult the latest HSE guidelines.

Logical arrangement by frequency or SKU type

Grouping products logically increases picking speed and accuracy, as workers can easily figure out where to look even if they're unfamiliar with the layout. Generally, high-demand SKUs should be stored in the most accessible locations, while slower-moving items can be placed higher up or further back.

Use of labels, colours and categories

Finally, introduce a bin labelling system for easy navigation using labels, colours and categories. These should be displayed clearly front and centre to avoid confusion.

Related reading: Industry Spotlight: Cable Ties & Tape for Manufacturing

Choosing the right storage bins

The next step is selecting the right storage bins, which ultimately depends on the amount of space and types of products you have.

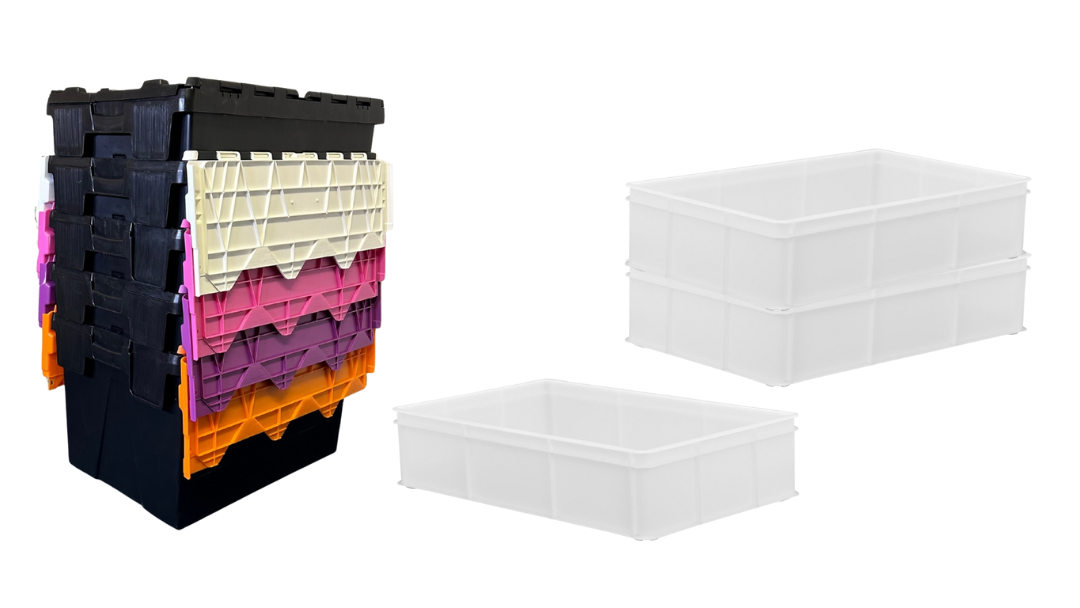

- Storage boxes with lids – Perfect for protecting products from warehouse grime. Better for long-term storage.

- Stacking containers – Ideal for saving space in compact areas.

- Storage bins, trays and crates – Suitable for small parts, fast-moving stock and hand-picking.

- Pallet and bulk containers – Designed for heavy or high-volume items. Most are collapsible or have drop-down sides for easy access.

One isn't necessarily better than the other – they just serve different purposes. Most warehouse picking stations use a combination of all four to maximise efficiency.

Planning your racking and layout

How you plan your layout depends on your environment. However, there are a few smart rules to follow, which we've covered in more detail below.

Leave space for overflow and restocking

Create buffer zones where excess stock and incoming deliveries can be stored temporarily without disrupting order fulfilment. There's nothing worse than today's warehouse picking station getting clogged up with tomorrow's products.

Implement a one-way flow where possible

A well-signposted, one-way route through the picking station prevents congestion and keeps workers moving efficiently. If this isn't possible, use clear floor markings to guide foot traffic.

Store fast-moving items near the start of the line

Position popular, high-volume items at the beginning of the line so pickers can grab them and go. As well as reducing congestion, this minimises the total amount of time workers spend at the station.

Use colour to distinguish parts or order zones

Alongside using colour to distinguish products, you can also use it to separate zones. For example, you might store urgent dispatch items in the "red zone" and slower-moving items in the “blue zone”.

Related reading: PPE & Disposable Gloves Buyers guides

Find the right storage bins for your picking station

In summary, the best warehouse picking stations are cleverly designed to guide pickers through the line with minimal delay. By using the right storage solutions and labelling systems, you'll completely revolutionise the order fulfilment process, saving significant amounts of money and time.

Ready to upgrade your setup? Browse the GTSE range of quality storage bins and racking today. For further support, contact one of our knowledgeable team members.