Battery and welding cables are toolbox must-haves for vehicle owners, auto electricians, off-grid installers and workshop buyers.

Both are used to conduct electricity in heavy-duty power setups, but there are a few key differences to keep in mind – especially when it comes to application and characteristics.

Not sure which one suits your setup? The following guide breaks it down.

Battery cables vs welding cables: Key differences

While battery and welding cables are both types of electrical cables, that's pretty much where the similarities end.

Battery cables

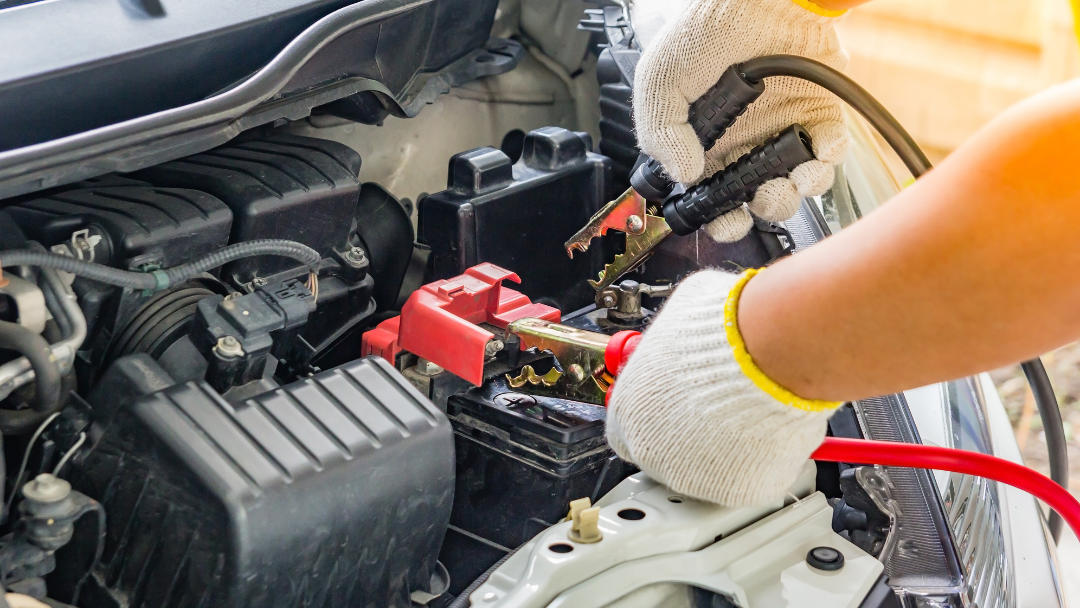

Battery cables are thick, insulated wires commonly used to connect a vehicle's battery to its starter or electrical system. However, you'll also find them in off-grid solar installations and backup power systems.

Generally, battery cables are less flexible than welding cables because they have thicker copper strands designed to handle high currents. Another key difference is insulation – battery cables tend to use polyvinyl chloride (PVC) or cross-linked polyethylene (XLPE), which offers good resistance to heat, chemicals and moisture.

Features include:

- High current capacity

- Thick-stranded copper conductors

- Moderate flexibility

- PVC or XLPE insulation

- Efficient over short runs

Welding cables

In contrast, welding cables contain hundreds to thousands of fine copper strands, making them exceptionally flexible. They're ideal for routing through tight spaces and around moving parts in automotive starter systems and inverter power supply connections.

Instead of plastic insulation, welding cables often use ethylene propylene diene monomer (EPDM) or neoprene. Both are temperature-resistant and highly durable, even in harsh outdoor environments.

Features include:

- High current capacity

- Fine-stranded copper conductors

- Superior flexibility

- Flexible rubber insulation (often EPDM or neoprene)

- Efficient over long runs

→ Shop our Battery & Welding Cables now

Related reading: Electrical Buyers' Guides

Key buying considerations

Whether you need a battery cable or a welding cable, you'll need to review the cable specifications before making a purchase. The checklist below covers the most important considerations, from voltage rating to polarity colour coding.

- Cable size (mm² / AWG) – Measured in square millimetres (mm²) or American Wire Gauge (AWG) and used to determine current-carrying capacity.

- Insulation type – Different insulations have different properties. For example, XLPE and silicone rubber can handle higher temperatures, while neoprene and fluoropolymer have superior chemical resistance.

- Voltage rating – Refers to the maximum voltage a cable can handle under normal operating conditions. Match this to the application environment.

- Temperature rating – Refers to the maximum and minimum temperatures at which a cable can safely operate.

- Flexibility – Some cables require greater flexibility to manoeuvre through and around moving parts and tight spaces. Flexibility is often determined by the amount and type of copper strands.

- Polarity colour coding – Indicates wire polarity. Positive wires are typically red and negative wires are black

- Length – How long do you need the cable to be? Consider full cable runs, including routing bends.

Here are a few real-world examples for reference:

- For a 12V starter motor in a car, a 35mm² (or 2 AWG) cable is typically used to handle the high current needed for engine starting.

- For inverter connections in off-grid solar setups, a 35mm² (2 AWG) welding cable is typically used for its flexibility.

- For heavy equipment, a 70mm² (1/0 AWG) battery cable is typically used to support high current demands and longer cable runs.

Don’t forget environmental factors

Choosing the right cable isn’t just about current capacity. It’s also about how well it can withstand environmental stress. Insulation materials play a key role in protecting both battery and welding cables from heat, UV exposure, chemicals, water and mechanical wear.

Battery cables (PVC / XLPE)

PVC insulation is economical and resistant to moderate heat, moisture and chemicals, making it ideal for indoor use, vehicle battery connections or solar setups. XLPE offers higher temperature resistance and improved chemical and abrasion protection, which is ideal for engine bays or slightly harsher environments. Both are durable over short runs but can become stiff or brittle under extreme cold or prolonged UV exposure.

Welding Cables (EPDM / Neoprene)

EPDM and neoprene provide superior flexibility, heat resistance and mechanical toughness. These materials resist oil, water and abrasion, making them great for outdoor solar installations, workshops and off-road vehicle use.

They maintain flexibility even in tight bends and rough handling, which is essential when routing cables around machinery or through engine compartments.

Real-world examples:

- Under the bonnet: XLPE battery cables withstand engine heat and occasional fluid spills. EPDM welding cables handle routing through vibration-prone, high-temperature areas.

- Outdoor installations: Neoprene welding cables resist UV and moisture in solar setups or off-grid vehicles. PVC battery cables may degrade faster if exposed to prolonged sunlight without protection.

- Workshops & garage floors: Flexible welding cables endure abrasion from tools and foot traffic better than stiff battery cables.

Common applications

So, when are battery and welding cables most often used? Let's take a look:

Battery cables:

- Connecting starter motors to vehicle batteries

- Emergency power setups and winches

- Solar system battery connections

- Powering off-grid systems in vans, boats or campers

Welding cables:

- Industrial welding machines and battery banks

- Inverter connections in mobile or compact systems

- Battery parallel and series linking in tight enclosures

- Connecting battery isolators in compact engine bays

Related reading: Industry Spotlight: Cable Ties & Tapes for Solar Farms & Panels

Installation tips and best practices

Proper installation of battery and welding cables ensures safety, efficiency and longevity. Follow these steps to achieve professional results:

Step 1 – Plan your route

Map out the cable path before starting. Avoid heat sources such as exhausts or engine blocks, and steer clear of moving parts. Ensure there’s enough slack to accommodate vibration and engine movement without straining connections.

Step 2 – Use protective measures

When routing cables through metal panels or tight spaces, install grommets, conduit or protective sleeves to prevent chafing. Maintain a proper bend radius, as sharp bends can damage strands and increase resistance.

Step 3 – Secure cables properly

Use clamps, cable ties or brackets to keep cables in place. Group related cables together for easier maintenance and reduced vibration stress.

Step 4 – Connect terminals safely

Strip insulation carefully without nicking conductors. Crimp or solder terminals with the correct tool, ensuring a tight, corrosion-free connection. Heat-shrink tubing or insulating boots provide added protection.

Step 5 – Check for voltage drops

After installation, test the circuit with a multimeter to verify that the voltage drop is within acceptable limits. A poor connection or undersized cable can lead to overheating or performance issues.

Step 6 – Regular inspection

Periodically check terminals and cable routing for signs of wear, corrosion or abrasion. Early detection prevents failures and extends the life of your installation.

Battery vs welding cables: Finding the right fit for you

While battery and welding cables both offer reliable solutions for high-current automotive and industrial setups, it's essential to choose the right one based on your specific power needs. Still unsure which cable is the right fit? Get in touch with a GTSE advisor today.