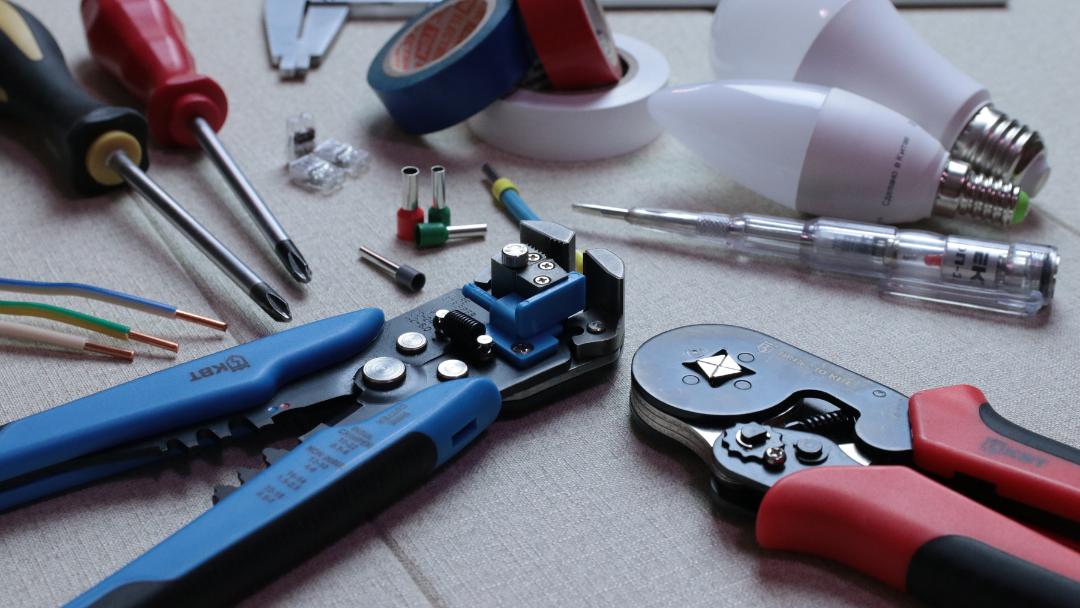

Having the correct crimping tool is the difference between a hack job and a secure, reliable connection. Wondering how to use crimping tools effectively? You’re in the right place. This guide covers:

- Choosing the right crimping tool for terminals

- Step-by-step guide to using crimping tools

- Crimping tool best practices

Understanding crimping tools

Put simply, crimping tools are specialised devices that join wires to connectors or terminals. The goal isn't to cut the wire but to apply enough pressure to bond them together – which is a faster alternative to screwing or soldering.

There are several types of crimping tools used across different industries. We've listed some of the most common below:

- Manual crimping tools – Hand-powered with plier-like handles. Suitable for DIY electronics and automotive repairs.

- Ratchet crimping tools – Hand-powered but feature a ratcheting mechanism that controls compression force. Ideal for professional use.

- Electrical crimping tools – Powered by a rechargeable battery. Perfect for repetitive, field-based work.

- Hydraulic crimping tools – Hydraulic pressure creates high-force crimps on thick cables, often found in large vehicles like boats.

- Pneumatic crimping tools – Air-powered for continuous use in high-volume manufacturing environments.

→ Shop our Crimping Tool Range now

Types of terminals and their crimping requirements

The secret to a reliable connection is matching the crimping tool to the terminal type, which we cover in the following sections.

Ring / spade terminals

As the name suggests, a ring terminal has a ring-shaped metal end that fits perfectly around a bolt or screw. In contrast, a spade terminal has a fork-shaped end that connects wires to screw terminals and posts.

Ratchet crimping tools are typically best suited for both, as the ratchet mechanism provides consistent, reliable crimps with controlled pressure.

Top tip: When using ratchet crimping tools, fully squeeze the handles until the ratchet mechanism releases automatically – this ensures a complete crimp.

→ Shop our Spade Terminal Range now

Insulated terminals

Insulated terminals have a plastic casing covering the metal conductor inside. This protects against short circuits and harsh environmental conditions.

They're commonly used in industrial control panels and machinery wiring, where durability is paramount. In this instance, electrical or ratchet crimping tools with insulated dies are most suitable.

Top tip: When using electrical crimping tools (and some ratchet tools), adjust the pressure settings for your terminal and wire gauge.

Non-insulated terminals

Non-insulated terminals don’t have a protective sheath, exposing the metal inside.

You'll often find them in heavy-duty electrical equipment, which uses more effective forms of protection, including hard outer enclosures (like signal boxes), heat-shrink tubing and sealants. In these cases, hydraulic crimping tools are ideal.

Top tip: Most hydraulic tools have an automatic stop function when the correct pressure is reached. Wait until the mechanism activates to ensure a tight crimp.

→ Shop our Non-Insulated Terminal Range now

Step-by-step guide to using crimping tools

Crimping doesn't have to be a chore. Simply follow the steps below.

- Step 1 – Select the appropriate terminal and crimping tool.

- Step 2 – Strip the wire to the correct length.

- Step 3 – Insert the wire into the terminal until there's no movement.

- Step 4 – Position the terminal in the crimping tool.

- Step 5 – Squeeze the handles and apply consistent pressure. Don’t rush, especially when using crimping tools with automatic stop features.

- Step 6 – Inspect the crimped connection. Gently tug the wire to check whether it’s secure.

Safety tips and best practices

Of course, safety matters to any experienced electrician, mechanic or technician, which is where crimping tool best practices come into play. Ask yourself the following questions before you begin (you should answer YES to all of them):

- Are you wearing protective gear?

- Are you working in a clutter-free environment?

- Are your crimping tools in good condition?

- Are your tools on stable surfaces?

- Have you secured loose clothing and tied back long hair?

Related reading: PPE & Disposable Gloves Buyers’ Guides

Why quality crimping tools matter

To summarise, investing in the right crimping tools for the job is the key to success – using pliers or other non-specialised tools will only cost you time and money. Speak to our team today for more advice on how to use crimping tools.