Whether you're a DIY enthusiast who wants to install a light fixture or an automotive technician specialising in vehicle electronics, you'll need high-quality wiring terminals to establish safe connections.

Sound complicated? Don’t worry. Keep reading as we explain the role of wiring terminals, how to choose the right ones for your job and tips for installing electrical terminal blocks.

What are wiring terminals?

In a nutshell, wiring terminals create secure and reliable connections between wires, cables and devices. Think of them like airport terminals where multiple paths meet – from here, electrical currents, much like passengers, are organised and rerouted to their intended destinations.

Electrical wire connectors typically consist of two components: a metal core made of a conductive material, usually copper or brass, and a plastic outer housing for insulation and protection.

Related reading: Electrical Buyer’s Guide

Common types of wiring terminals

There are different types of wire terminals for specific jobs. For instance, ring terminals are perfect for general car repairs that don't require soldering, whereas push-in wire connectors simplify the process of replacing light switches and outlets.

Keep reading as we run through the six most common wire connector types:

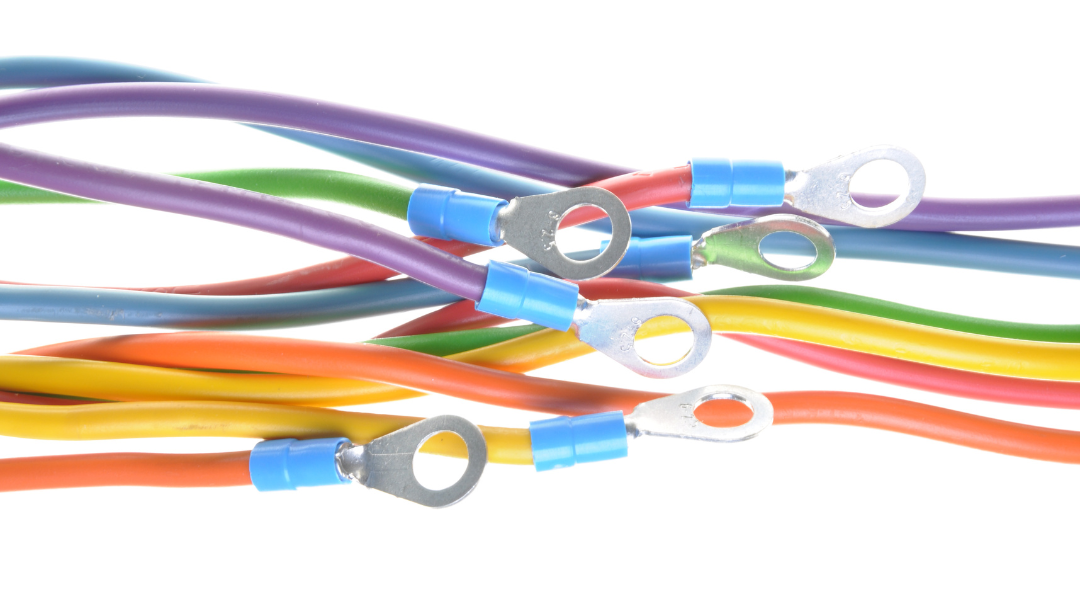

Ring terminals

As the name suggests, ring terminals have a ring-shaped metal end that connects to studs and screws. When fastened down, they provide a secure, vibration-resistant connection that's excellent for high-current conditions.

Real-world example: Connecting a car battery's ground wire to the chassis. Ring terminals won't shake loose from engine vibration.

Spade terminals

Spade terminals, also known as spade connectors, allow easy attachment and removal from screw-type terminal blocks. They are especially useful if you need to frequently disconnect the connection for maintenance.

Real-world example: Wiring a thermostat in HVAC systems. HVAC control boards often have screw-type terminal blocks.

Butt connectors

Butt connectors are frequently used to connect or splice two wires together, especially when creating wire extensions or making temporary connections.

Real-world example: Repairing industrial-grade equipment. Splicing wires together ensures minimal downtime.

Quick disconnects

Quick disconnects facilitate the rapid connection and disconnection of wires without requiring tools, making them ideal for quick fixes or on-the-go repairs.

Real-world example: Replacing car headlights or taillight bulbs.

→ Shop Quick Disconnectors now

Push-in wire connectors

Like quick disconnect terminals, push-in wire connectors streamline the process of connecting wires without tools. Simply strip the insulation, then push the wire end firmly into the connector.

Real-world example: Swapping out an old ceiling light for a new one.

Screw terminals

Screw terminals provide a reliable connection by securely clamping wires with screws. They are used in both high-current and low-voltage control circuits.

Real-world example: Railway signalling equipment uses screw terminals because they can withstand regular inspections and maintenance.

Factors to consider when choosing wire terminals

Wondering how to pick the right electrical wire connectors? Here are a few key considerations to help you make the smartest and safest choice.

- Wire gauge compatibility – Ensure the terminal fits the wire size

- Current and voltage – Match wire terminals to electrical loads

- Environment – Choose materials for moisture, temperature and vibration

- Installation method – Will you be crimping, soldering or screwing?

- Ease of maintenance – How often does the terminal need to be disconnected for maintenance?

Related reading: Cable Management Buyer’s Guide

Installation tips and best practices

Installing electrical terminal blocks isn't complicated if you follow a few straightforward tips. Firstly, turn off all power sources beforehand and use the correct crimping tools (pliers don't apply enough pressure to secure the connection).

While everyone's technique varies depending on the project, you should always:

- Only strip the necessary length of insulation

- Inspect before crimping – you may need to replace or trim damaged wire

- Make solid crimps that compress the wire and terminal tightly

Afterwards, test the connection by gently tugging the wire.

Where can I buy quality wiring terminals?

Now you know your options, browse the GTSE website for quality crimp terminals and electrical wire connectors. Our comprehensive range includes everything you need to complete large-scale commercial contracts and home DIY projects.