Industry Spotlight: Cable Ties & Tape for Manufacturing

Posted by Cris on 10th May 2024

This article highlights two significant tools that are

critical in helping manufacturing operations run with ease are cable ties and tape. The cable tie and tape always appear to be simple tools but actually plays

a crucial role in enhancing efficiency and safety in and around the various

production environments.

- 1.Safety

Safety is always the top priority in environments where there is constant fast paced processes and heavy machinery. Cable ties and tape are able to contribute to overall safety in several ways; for example, they secure cables away from moving parts, they lower the risks of falls and preventing accidental damage to electrical wiring, and they can securely bundle and fasten cables and wires together. On that same trajectory, tape in its various forms (brightly coloured or reflective tape) can be utilised as visual cues. They can be used to mark safety zones, emergency exits, and other hazardous areas, which promotes compliance with safety regulations and standards.

- 2.Improving Quality Control and Traceability

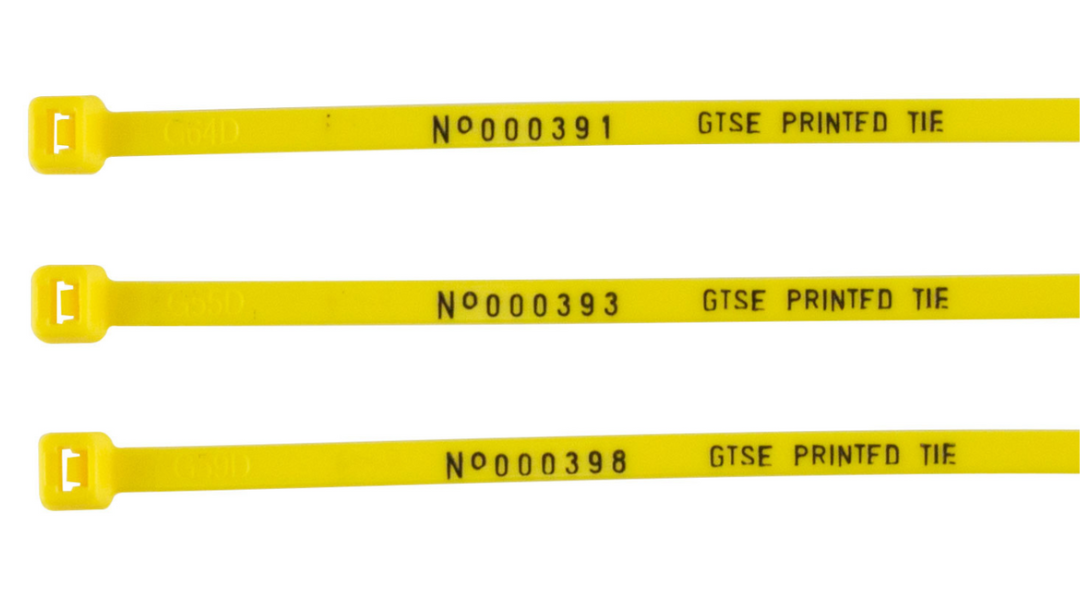

Being able to track and document material is vital in any manufacturing process. It is vital to use cable ties and tape that have methodical labelling features since this provides the means to mark components, products, and packaging with information such as serial numbers, batch codes, and production dates.

Using printed cable ties is a great way to allow items to be traced easily before, during and after the manufacturing process.

- 3.Organising Assembly and Production Process

Another key component of assembly and production is making the process as efficient as possible. This is another way cable ties and tape become significant. Some examples of how help to make operations efficient are by securely fastening components, securing wires, and ensuring proper alignment of parts.

We also know that cable ties and tape can prevent tangling, reduce clutter, and make better use of space. This method of organisation improves workflow productivity but also, more significantly, allows for easier maintenance and troubleshooting of equipment. Whether in car manufacturing, electronics assembly, or appliance production, cable ties and tape can provide reliable support, allowing workers to focus on precision and quality in their tasks.

- 4.Anti-Vibration and Shock Absorption

Manufacturing environments that are prone to vibrations and shocks, such as automotive assembly lines or heavy machinery operations, can use specialised cable ties and tape with vibration-resistant properties. These specialised items come in use as additional protection against mechanical stress. These items help prevent cables from loosening or becoming damaged from the constant movement. In this way specialised cable-ties and tapes reduces equipment failure and also limits exposure to risk factors for workers.

Similarly, cable ties and tape can help towards noise reduction in environments where vibrations cause noise concern. You can use cable ties or tape to secure objects that have become lose from vibrations, or indeed, use these tools to attach supplementary noise dampening products. Since noise and vibration become reduced using cable ties and tape, these tools contribute to an overall quieter and more comfortable working environment, enhancing operator comfort and productivity.

- 5.Modular Manufacturing and Quick Changeovers

In industries embracing modular manufacturing and rapid changeovers to accommodate diverse product lines, cable ties and tape provide flexible solutions for reconfiguring production setups. Quick-release cable ties and easily removable tape help generate swift adjustments to machinery layouts, enabling manufacturers to adapt to changing production demands with minimal downtime.

- 6.High-Temperature Applications

Manufacturing processes that involve high temperatures, such as metal fabrication, foundries, or glass manufacturing, especially require cable ties and tape. Cable ties and tape are often designed to withstand extreme heat. Heat-resistant materials, like stabilised nylon, ensure that cable ties and tape maintain their integrity and performance, even under prolonged exposure to elevated temperatures. This feature helps to prevent melting, degradation, or overall production failure.

Conclusion

Cable-ties and tape can be used with innovation and efficiency, especially in any manufacturing industries. From streamlining organisation and facilitating assembly processes to ensuring safety compliance and supporting lean manufacturing principles, these tools play a versatile role and is a catalyst of productivity.