How Electricians Use Cable Ties: Safety, Labelling & Fixings

24th Jul 2025

Electricians, all over the world, have always relied heavily on cable ties as an essential tool in various aspects of their work. The most valued uses of cable ties is for the safety, labelling, and fixing of electrical wires. GTSE cable ties support the efficient organisation and management of untidy electrical wires to reduce potential safety hazards and damage to the wires themselves. Colour coded ties help electricians to easily identify specific areas and reduce time wasted.

Other than individual organisation and safety there are also legal requirements for electrical installations. The 18th Edition was introduced to address cable support and identification. Further below This article is going to showcase some of GTSE’s products which have a proven track record on delivering high quality electrician cable management.

Core Cable Tie Applications and Uses:

One of the main strengths of using good quality cable ties is for effective wire bundling within consumer units and panels. Poor quality cable ties and fixings can create issues such as shifting, and loosening around electrical units and panels, and can result in the wires rubbing. Continuous wire rubbing, over time, can encourage fire hazards. With reliable cable ties, electricians avoid hazards – and maintain trust over every contract.

Another issue some contractors may face at services is disorganised wiring systems. Colour-coded cable ties are a quick and easy fix to identify different circuit systems. Not only is this beneficial for visual reference, but can also hugely help highlight the areas where the rewiring work is needed. For all electricians this has been proven to save time and effort on contracts, and reduces wiring mishaps.

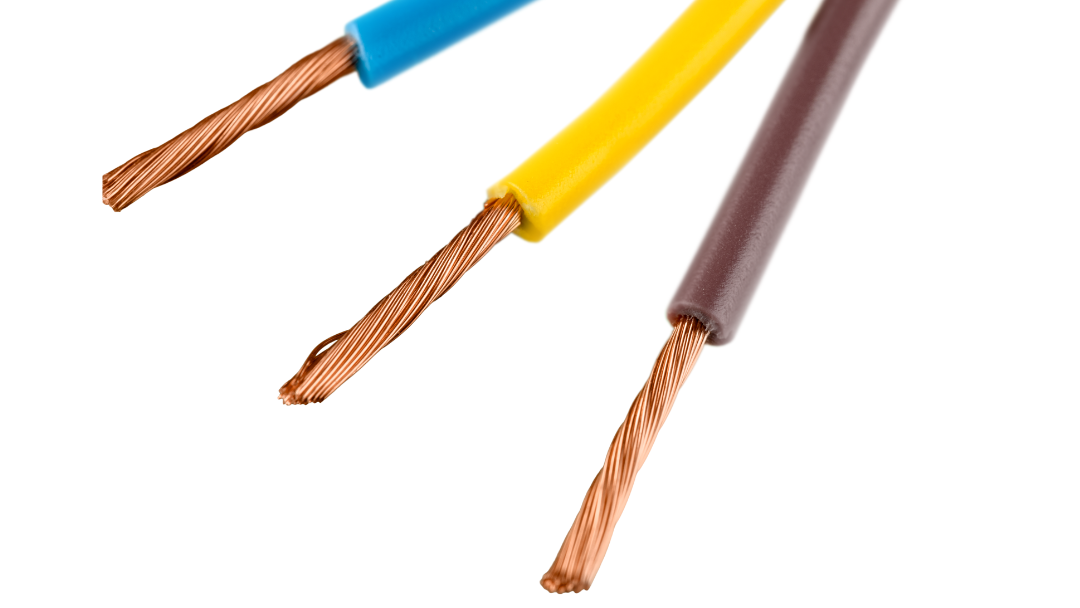

An example of the dangers electricians can face for having incorrectly colour coded wiring and cable tie systems is that they may interfere with a live wire. This can cause significant risks to both the electrician and may also permanently damage the circuit systems. To overcome this issue, brown cable ties can be used to portray and identify live wires.

Electricians need to be able to secure wires to a range of different surfaces at professional wiring installations. GTSE provides a range of different products to support cable tie fixing, and securing the wiring over a long period. Anchors, bases, and fixings are vital for securing wiring over a range of walls, panels, and floorings which won’t interfere with circuit connections and result in faults for appliances.

18th Edition Compliance:

In January 2019, the 18th Edition British standard wiring regulation, also known as BS7671, was introduced to cover a wide variety of issues that could arise during wiring installation. The new regulations have stated that plastic fixings are now illegal and are not allowed to be the main support to hold wires in position. Additionally, this is followed by a statement highlighting that wiring is not to be installed on combustible building materials.

GTSE understands that electricians need a quick, fast solution for replacing plastic supports. Steel and metal cable fixings have been launched with fast delivery for electricians, to ensure their customers are compliant with the regulations. Stainless steel cable ties are specifically designed and tested to be 18th Edition compliant.

Our Recommendations:

GTSE can provide a range of high-quality products to support each electrician's needs to ensure that you are complying with the 18th Edition wiring regulations. Below are a few situations that electricians and contractors may face, and appropriate direction to manage them:

Standard Indoor Installations:

Nylon ties are a suitable option for standard indoor installations as they are not prone to UV exposure. The length and width are flexible when purchasing with GTSE so you can be adaptable for different contracts and clients Black Nylon Cable Ties (Pack of 100).

Fire Safety:

For outdoor projects UV exposure can cause a risk to cable management as it can degrade the material and begin to expose live wiring. GTSE have introduced UV resistant cable ties to reduce this risk of overheating and causing fires. A secondary benefit of using GTSE’s UV resistant cable ties is that they are also resistant to weathering and ageing making them suitable for large outdoor projects Black UV & Heat Resistant Cable Ties (Pack of 100).

High Temperature Installations:

During high temperature installations regular cable ties are not suitable as it will cause them to melt and effect wire positioning. At GTSE you can purchase 18th Edition Stainless Steel cable ties which can sustain temperatures of up to 540°C. These are appropriate for working around areas such as boilers, and heating systems Stainless Steel Cable Ties - 316 Marine Grade (Pack of 100).

Visual Reference:

Colour-coded cable ties allow electricians to quickly identify different cables and circuits. Not only does it complement organisation, navigation and safety but, they can avoid labelling issues. Some wire labels may be in difficult areas to read, or may begin to peel. An electrician who uses colour coded cable ties will be able to navigate the electrical wiring system at a glance - Colour Variety of Cable Ties at GTSE.

Cable Ties Fixing & Accessories:

Accessories are an important pairing to support cable wiring management and fixing. It is vital for electricians to apply suitable cable ties to improve the quality of installations. Below are details of some appropriate fixing accessories for future installations:

Adhesive Backed-Bases:

Adhesive backed bases are a suitable quick fix for securing cable ties to flat surfaces. For these mounts, no tools are needed as you can peel and stick to their designated location. One issue that they overcome is that certain surfaces are unable to support a screw on mount. For example screws would not secure properly in plywood. With loose screws, wiring placement would not meet regulation expectations Black Self Adhesive Cable Tie Bases (Pack of 100).

Screw-Mount Bases:

Screw-mount bases are perfect for electricians to provide long-term stability for cable ties on flat surfaces. They also provide a more sustained solution for outdoor wiring circuits as they are more adaptable to withstand harsh weathering without becoming misplaced - Black Cable Tie Screw Mount Saddle Base (Pack of 100).

Cable ID Tags:

To follow BS7671, cable ID tags have become a more important accessory for circuit management. They enable electricians to quickly identify wiring when under modification, or testing. Additionally, cable ID tags are a cost-effective solution to prevent long-term electrical faults to immediately label a hazard once located - Plain ID Self-Tie Tie Tags (Pack of 14).

Tie Guns:

Electricians need cable tie guns to produce clean cuts whilst maintaining cable tie tension. Cable tails are an unnecessary interference once they have been secured, as they provide no purpose. GTSE provides a great value tie gun that is compatible with both nylon and stainless steel cable ties that automatically cuts the tail off when tension is achieved - Cable Tie Installation Tool.

Why Should Electricians Shop with GTSE?

GTSE is trusted by electricians all over the UK for delivering efficient, and excellent service. Take a look at what others have to say about us. We offer a range of high-quality products that will ensure safe electrical installations no matter the project size. All our products have been designed to comply with all of the 18th Edition Compliance regulations.

Shop with GTSE - giving electricians the best solutions with fast and efficient delivery. We’re here for you when you need us.