This buying guide on screws will explain to you the most common types of screws in use today, what they can be used for and how to choose the right type of screw. It also highlights some key factors worth considering before purchasing the best screw for you.

What Are Screws Used For?

Screws are an effective tool to create a strong mechanical hold; it fastens two objects together securely but, more importantly, is also really easy to remove. They are commonly used in construction, woodworking, metalworking, and various other industries for assembling, joining, or attaching components.

How Do Screws Work?

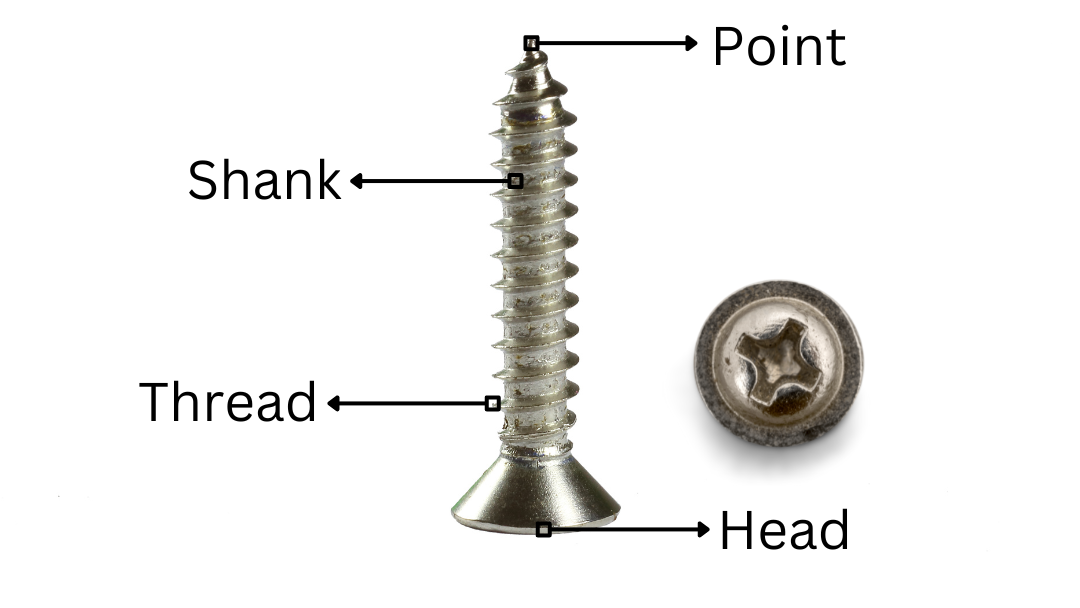

Screws have four main portions. The head, shank, thread and point. The screw has a long metal tube with threads that spiral up and down it. The head of the screw has a groove where you can use a screwdriver to rotate the screw. The effectiveness of a screw is dependent on the width of its thread and the gaps between them.

How to Select the Right Type of Screw for the Right Situation

To choose the right type of screw for a specific situation, follow these 10 steps:

- Identify the Material:

Determine the materials you'll be working with, such as wood, metal, or plastic. Different materials require screws with specific characteristics for optimal performance. - Consider the Load:

Assess the weight or load the screw will need to support. Heavier loads may require screws with thicker shafts or stronger threads. - Check the Thread:

The thread pattern (coarse or fine) and pitch should match the material. Coarse threads work well with softer materials like wood, while fine threads are suitable for harder materials like metal. - Length and Diameter:

Ensure the screw is long enough to provide a secure hold but not so long that it protrudes. The diameter should suit the size of the hole and the load requirements. - Head Type:

Different head types (flat, round, pan, hex) have varying applications. Choose one that suits your aesthetic and functional preferences. - Corrosion Resistance:

If the screws will be exposed to moisture or outdoor conditions, opt for screws made from corrosion-resistant materials like stainless steel. - Drive Type:

Consider the ease of use and the tools you have available. Common drive types include Phillips, Slotted, Torx, and Hex. - Pilot Holes and Pre-Drilling:

Depending on the material, you may need to create pilot holes or pre-drill to prevent splitting or cracking. - Quantity:

Estimate the number of screws needed for your project to avoid running out or having too many leftovers. - Safety Gear:

Always use appropriate safety gear, such as safety glasses and gloves, when handling screws and power tools.

What are Screw Gauges?

A screw gauge, also known as a thread gauge or pitch gauge, is a measuring tool designed to determine the size and specifications of screws, bolts, and other threaded fasteners. It plays a significant role in ensuring the accurate selection and fitting of screws for various applications.

The following table illustrates the relationship between imperial gauge sizes and metric screw sizes and gives the clearance and pilot hole sizes needed for each gauge size:

|

|

|||

|

Imperial |

Metric |

CLEARANCE HOLE |

PILOT HOLE |

|

2 |

2mm |

2.5mm |

1.6mm |

|

3 |

2.5mm |

3mm |

1.6mm |

|

4 |

3mm |

3.5mm |

2mm |

|

6 |

3.5mm |

4mm |

2mm |

|

8 |

4mm |

5mm |

2.5mm |

|

10 |

5mm |

5.75mm |

3.5mm |

|

12 |

5.5mm |

6.5mm |

3.5mm |

|

14 |

6.5mm |

6.5mm |

4mm |

Key Considerations when Buying Screws

As noted above, there are several things to factor in before buying screws. But primarily, the most important things to consider is:

What quantity of screws is needed? - Screws are sold either singularly or in packs of varying quantities and types. As such, it is worth checking how many you will need and the type you will need to save money and time.

Any Existing Screws? - If there are screws already in place for your project that you want to change for aesthetic or durability reasons, then check the screw head type if you’re looking to just replace them.

Safety - Don't forget to invest in appropriate safety gear, such as safety glasses and gloves, when handling screws and power tools.

By carefully considering all the above factors, you can make informed decisions when purchasing screws, ensuring they are well-suited for your project and provide reliable and secure fastening.