Washers are small, flat, and typically circular-shaped hardware components used in various applications to perform several functions. They are usually made of metal, plastic, or rubber and are placed between two parts, such as nuts and bolts or screws and the surfaces they are fastened to. They have a range of purposes.

What is the Purpose of a Washer

At a glance, the purpose of a washer is:

Load Distribution: Spreading the force from a fastener over a larger area to prevent damage.

Surface Protection: Preventing damage to materials when fastening.

Spacing and Alignment: Creating gaps or ensuring proper alignment.

Preventing Loosening: Keeping fasteners from coming loose due to vibrations.

Sealing: Creating watertight or airtight seals in plumbing and similar applications.

Electrical Insulation: Preventing electrical conductivity in electrical applications.

The Size of Washers

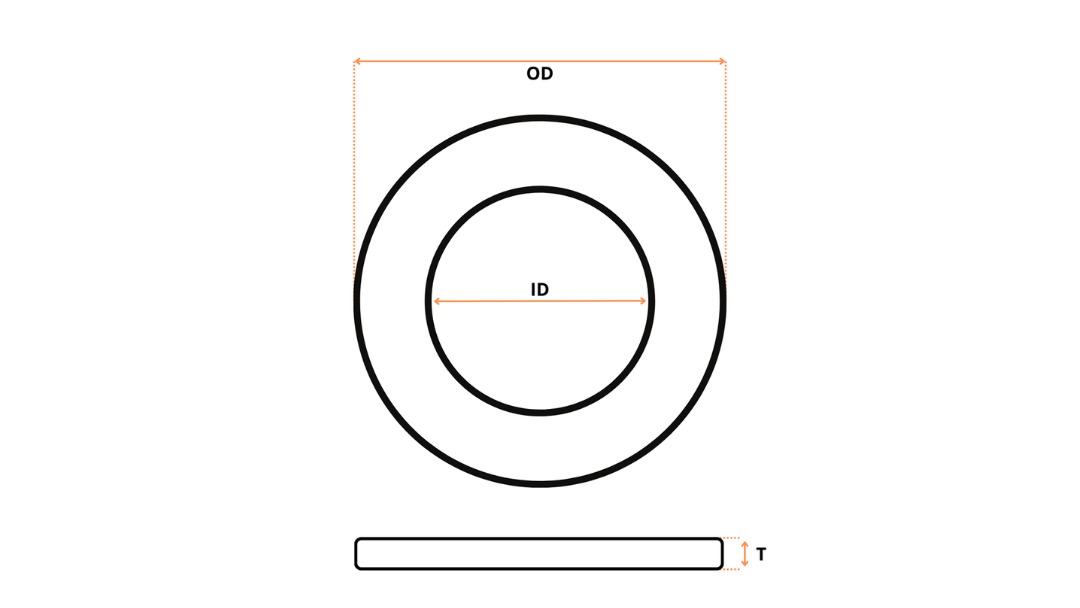

Washers come in various sizes to match the needs of different fasteners and applications. The size of a washer typically refers to its inner diameter, outer diameter, and thickness.

Here's a general guideline:

Inner Diameter (ID):

This is the size of the hole in the middle of the washer. It should match the size of the bolt or screw you're using.

Outer Diameter (OD):

This is how wide the washer is from edge to edge. It can vary, with larger ones providing more support.

Thickness:

This is how thick the washer is. It’s similar to measuring the height of a small, flat disk.

Common washer sizes include:

- Small washers, often with inner diameters ranging from 1/8 inch (3.18 mm) to 1/4 inch (6.35 mm).

- Medium-sized washers, with inner diameters between 5/16 inch (7.94 mm) and 3/8 inch (9.53 mm).

- Large washers, typically with inner diameters starting at 1/2 inch (12.7 mm) and going up to several inches.

In addition to these common sizes, washers can be found in many specialty sizes to meet specific application requirements.

Washer Material

Washers can be made from various materials, and the choice of material depends on the specific application and the properties required. Here’s a breakdown of some common washer materials sold at GTSE and their typical uses:

|

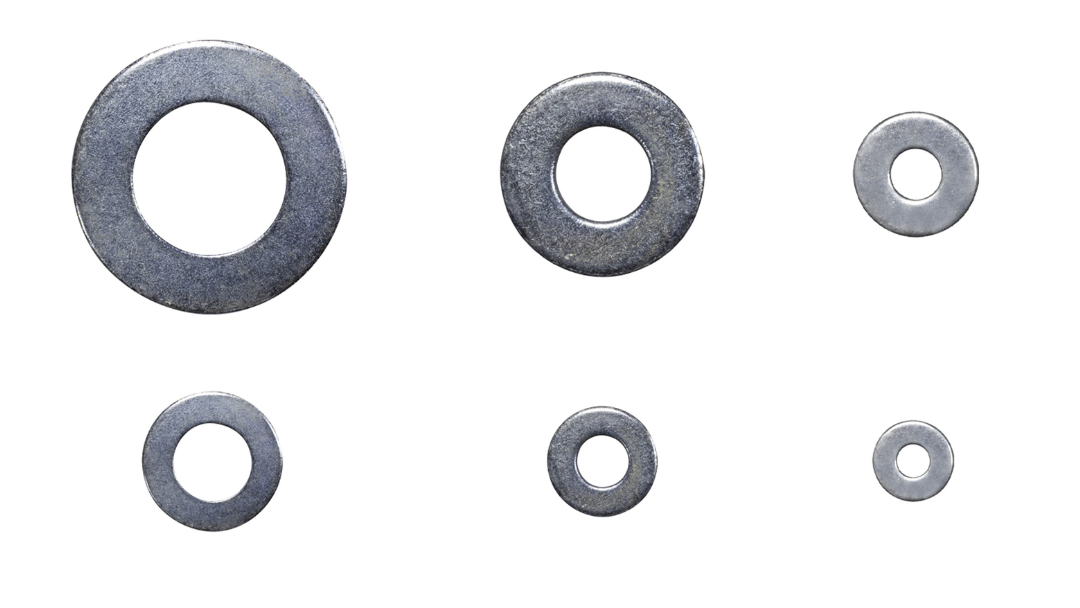

Flat Washers: |

|

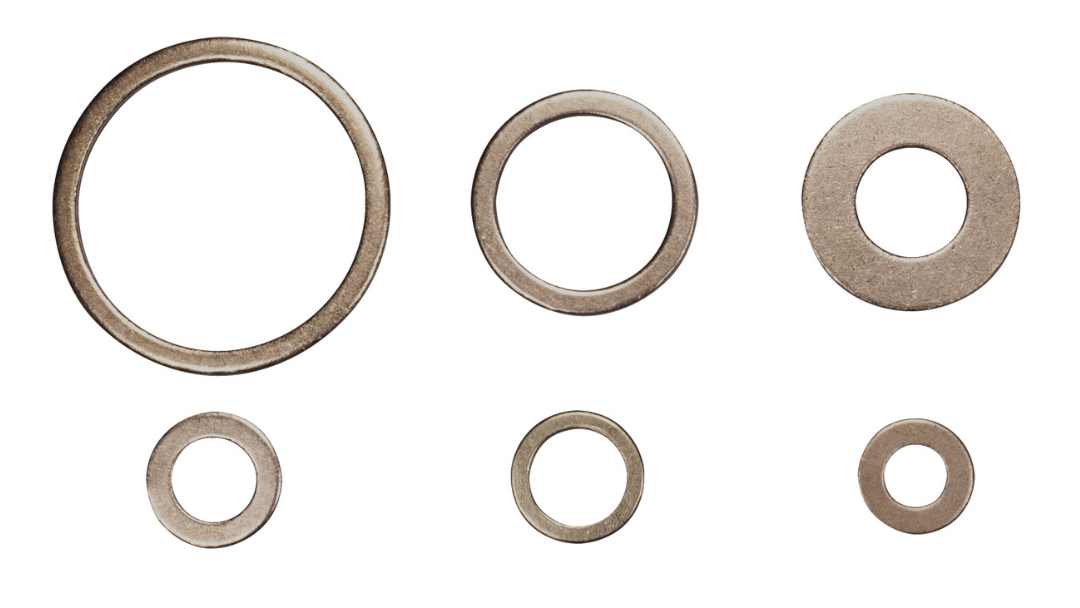

Copper Washers: |

|

Copper Compression Washers: |

|

Spring Washers: |

|

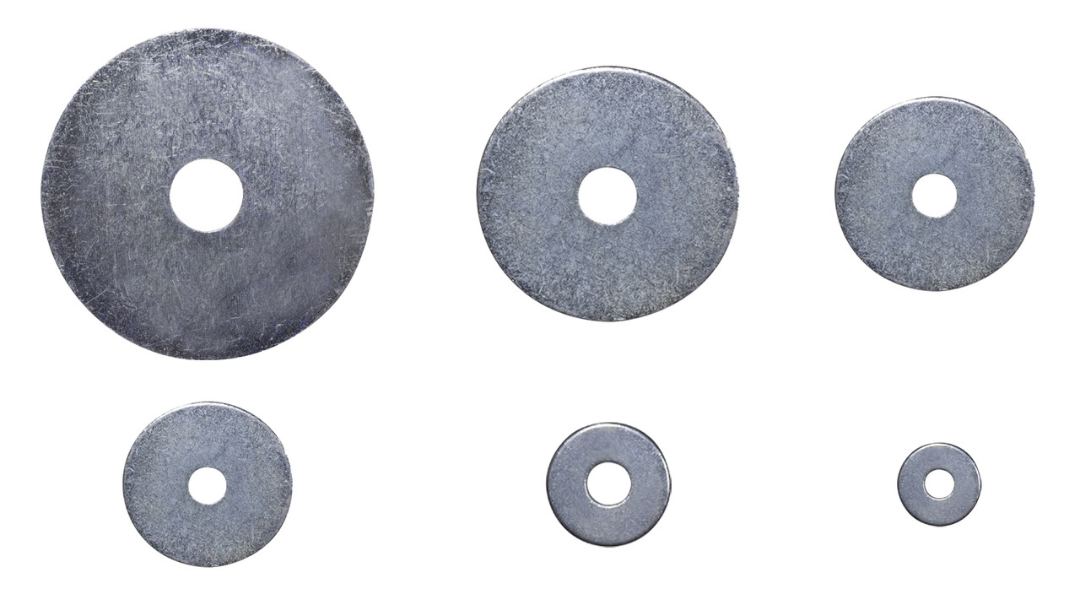

Repair Washers: |

|

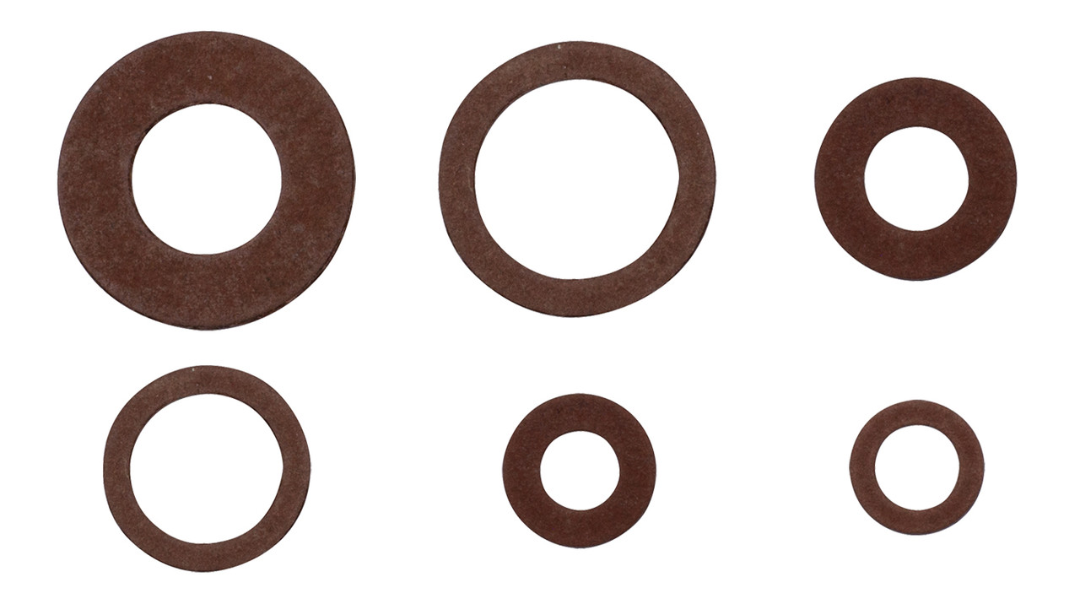

Fibre Washers: |

|

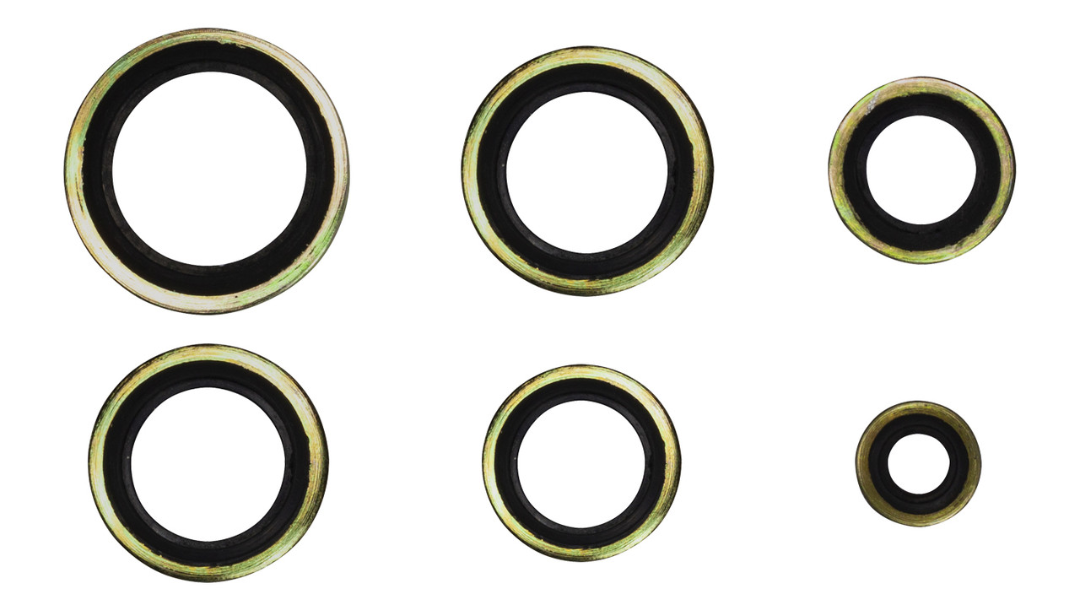

These washers consist of a metal washer bonded to a rubber or elastomer seal. They create a watertight or airtight seal and are commonly used in hydraulic and pneumatic systems. |

|

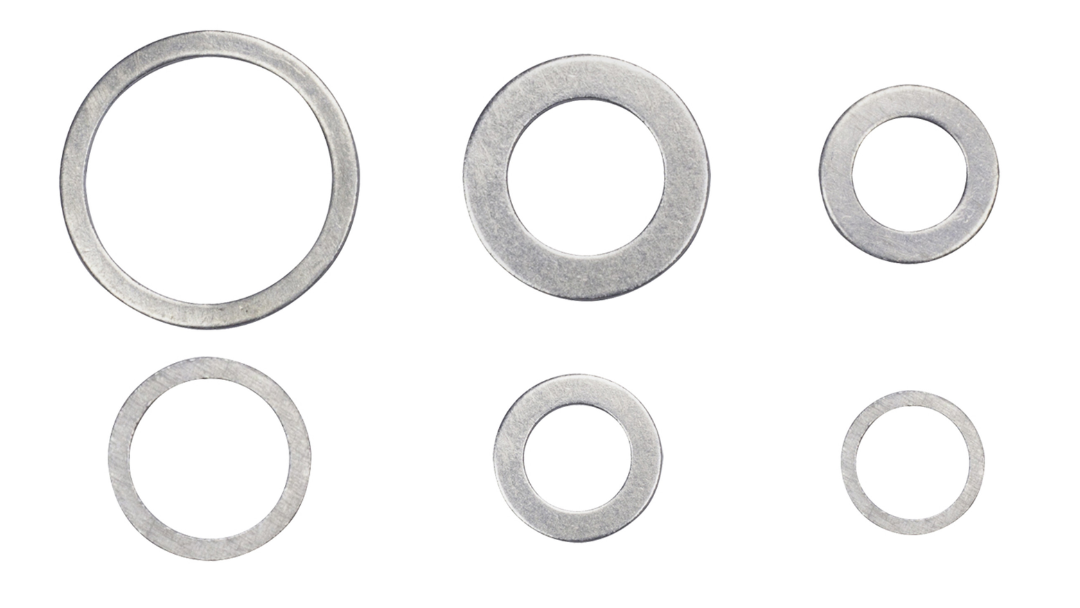

Aluminium Washers: |

|

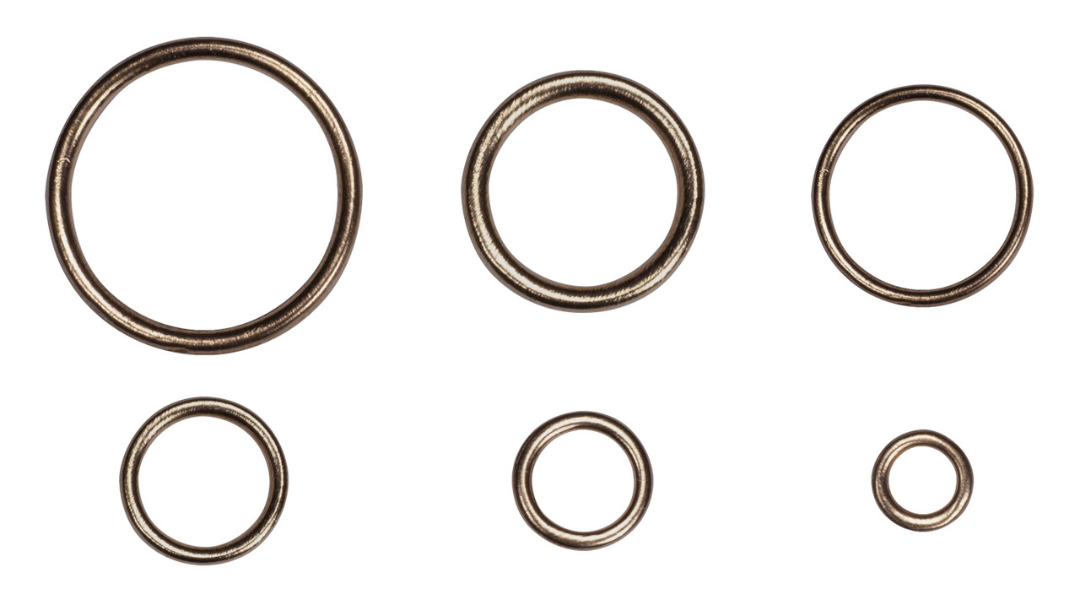

Rivet Washers: |

Each type of washer serves a specific purpose based on its design and material properties. Choosing the right washer for your application ensures that your fasteners are secure and that they meet the specific needs of your project.