There are a variety of screws available on the market, each one designed for specific purposes. In this article we review the common type of screws GTSE sells and understand their shape, threading, and head style.

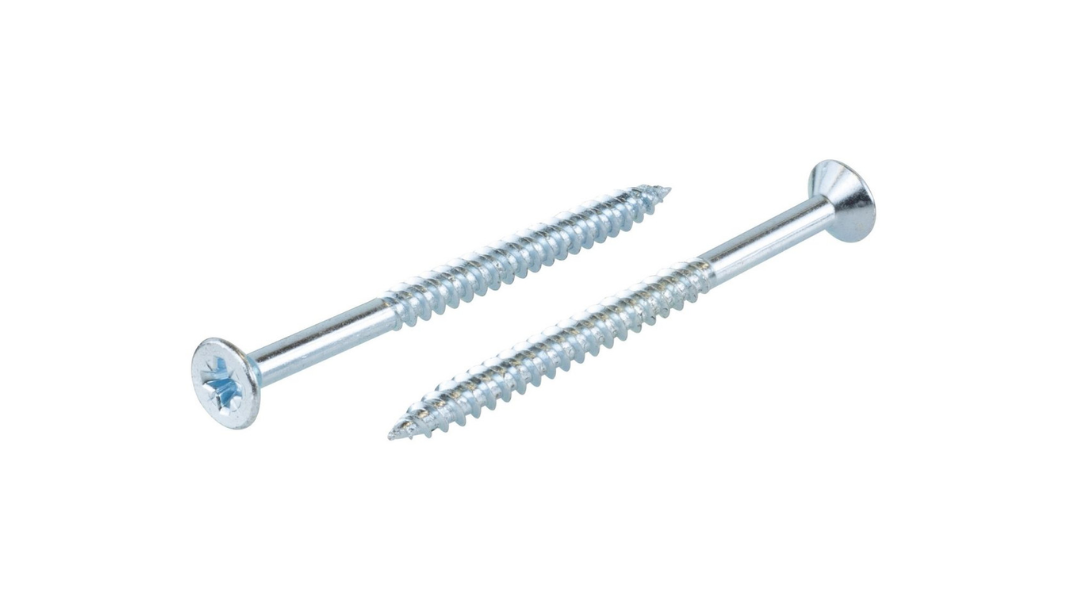

Wood Screws

Used for woodworking applications, these screws have coarse threads and a pointed tip to bite into wood effectively.

Set Screws

Set screws, also known as grub screws or blind screws, are threaded fasteners that are designed to secure an object within or against another object. Unlike most screws, set screws don't have a head that protrudes above the surface. Instead, they are fully threaded and feature a hexagonal socket or an Allen key recess on one end.

Flat Decking Screws

Flat decking screws are specialised fasteners designed for outdoor applications like attaching decking boards to wooden substructures. They usually have a flat, countersunk head that sits flush with the surface of the wood, reducing the risk of splintering and providing a clean finish. The threads on flat decking screws are coarse and self-tapping, making installation easier and more efficient.

Machine Screws

Machine screws are versatile fasteners commonly used in machinery, appliances, and electronic devices. They have finer threads and come with a variety of head types, including pan, flat, oval, and round heads. Machine screws are used with nuts or tapped holes and provide secure fastening.

Self-Tapping Decking Screws

Self-tapping decking screws combine the features of self-tapping screws with those of decking screws. These screws penetrate and fasten materials like wood or composite decking without the need for pre-drilling. They often have a specially designed thread pattern that cuts into the material as the screw is driven in, creating its own thread.

Self-Drilling Screws – Hex Head & Pan Head

Self-drilling screws, are engineered to drill their own holes as they are driven into the material.. Self-drilling screws come in various head styles, including hex head and pan head. The hex head provides a larger surface for applying torque, while the pan head has a rounded top that sits above the material surface.

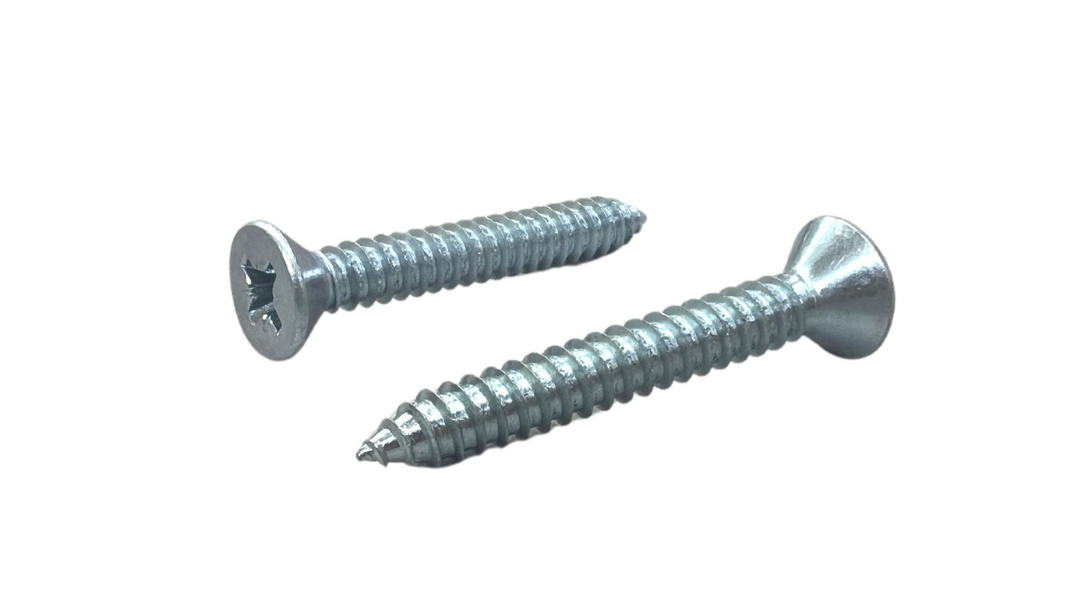

Self-Tapping Screws Black & BZP

Self-tapping screws, available in black and BZP (bright zinc-plated) finishes, are screws that create their own threads as they are driven into the material. The black finish is often used for a discreet appearance or to match certain materials, while the BZP finish provides corrosion resistance. These screws are used in a wide range of applications, from woodworking to metalworking, where a strong and reliable fastening is required.

Other common screws also include:

Sheet Metal Screws: Designed for attaching metal sheets or thin materials, these screws have sharp threads and a flat or rounded head.

Drywall Screws: These are designed for attaching drywall to studs, these screws have a coarse thread and a bugle-shaped head.

Furniture Screws: Furniture assembly often requires uniquely shaped head shapes for aesthetic reasons.

Security Screws: These are designed to stop any tampering. These screws have unusual drive styles that require specialised tools to remove it.

Micro Screws: These are really tiny screws used for delicate electronics and miniature applications.

There are many more specialised types of screws available, each tailored to specific needs. Moreover, GTSE sell assorted boxes of screws alongside singular screw items.

How to Safely Insert and Remove Screws

Inserting Screws:

Choose the right screw based on material and load. Pre-drill if needed. Use the correct driver, align the screw, and start slowly. Keep the tool straight and drive the screw gradually until flush. Avoid over-tightening.

Removing Screws:

Select the proper tool, apply penetrating oil if stuck, grip securely, and turn slowly. Try a back-and-forth motion for stubborn screws. Consider a screw extractor for severe cases. Apply controlled force to prevent damage. Replace damaged screws if necessary. Be patient and follow safety guidelines.

It's important to choose the right type of screw for your specific application to ensure proper functionality and durability. Whether you're securing decking boards, assembling machinery, or fastening metal components, selecting the appropriate type of screw will help you achieve the best results.