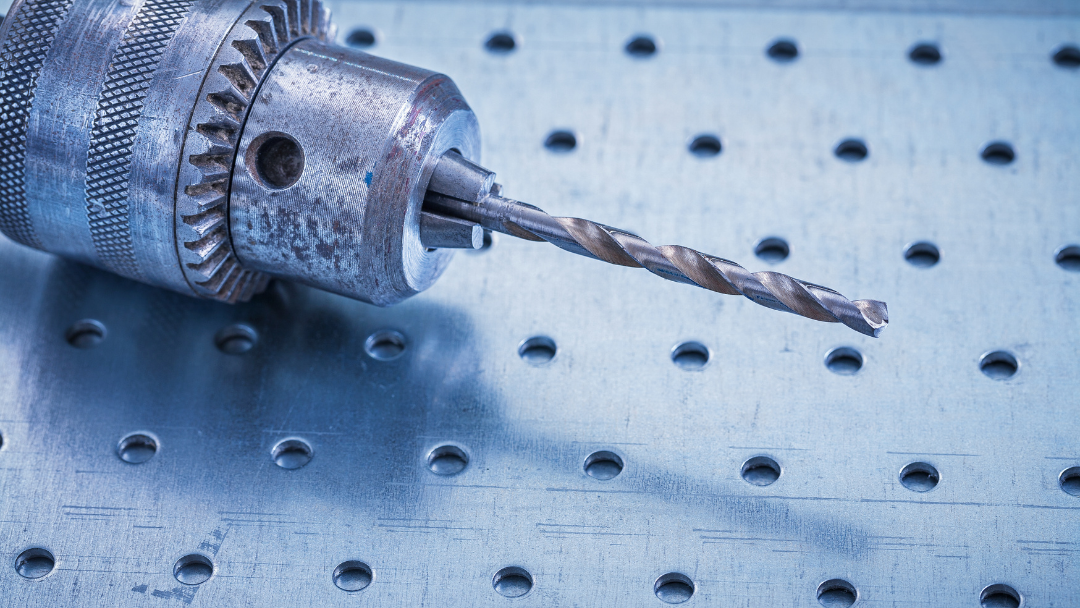

Preparation is key when it comes to drilling and tapping. In addition to familiarising yourself with safety measures and selecting the appropriate power tools, incorporating a Drilling and Tapping Spray into your process is a crucial step that guarantees a flawless outcome and extends the longevity of your tools.

Why Choose the Right Lubricant

Using a drilling and tapping spray is important for several reasons:

- Lubrication: Drilling and Tapping Spray acts as a lubricant to reduce friction between the tap and the material being drilled and tapped. This helps to prevent wear and tear on the tap, prolonging its life and improving accuracy.

- Cooling: Drilling and tapping generates heat, which can cause the material to expand and the tap to bind or break. Drilling and Tapping Spray helps to cool the area and reduce heat build-up, improving the quality of the finished product.

- Chip Evacuation: Tapping creates metal chips that can become trapped in the threads and interfere with proper thread engagement. The spray helps to flush chips out of the hole, reducing the risk of contamination and improving thread quality.

- Rust Prevention: Drilling and Tapping spray contain rust inhibitors that help to protect the material and tap from rust and corrosion. This prolongs the life of the threads and helps to ensure that they function properly over time.

- Galling Prevention: Galling is a phenomenon that occurs in metal when two surfaces that are in sliding contact experience high surface pressure and friction. This results in the transfer of material from one surface to the other, creating a rough and uneven surface that can cause the parts to stick or seize together. Lubrication, such as cutting oil or tapping spray, helps to reduce friction and pressure between the surfaces, reducing the risk of galling.

By using a drilling and tapping spray, you can improve the quality of the finished product and extend the life of your tools.

Drilling and Tapping Spray

The Drilling and Tapping Spray proprietary formula reduces friction, prolonging tools and machine life. The Spray applies an economical film of metal cutting fluid directly to the cutting zone, making it particularly suitable for large and difficult to reach areas. Gain a competitive advantage by drilling, cutting and tapping faster with less heat and the right amount of lubrication; and reduce downtime due to broken tools or overheating. The Drilling and Tapping Spray increases production at lower costs with minimal maintenance.

Where to use Drilling and Tapping Spray:

- Board Drilling

- Countersinking

- Tapping

- Threading

- Reaming

- Broaching

- Engraving

- To prevent galling

|

Advantages |

Disadvantages |

|

Improves finish |

Flammable |

|

Increases tool life |

Environmental impact: These sprays can release pollutants into the air and contribute to air pollution. |

|

Permits heavier cuts |

Health hazards - Repeated exposure can cause dryness of eyes and skin. Can cause drowsiness |

|

Reduces heat |

Limited application - Drilling and Tapping Spray may not work well on certain materials, such as certain plastics and composites. |

|

Fold down application nozzle for clean storage |

Unless properly maintained, Drilling and Tapping Spray can leave behind a residue that can clog the drilled or tapped hole, reducing its effectiveness. |

Overall, the Drilling and Tapping Spray is a valuable tool for those looking to improve efficiency, produce better results and extend the lifespan of their drilling and tapping tools.

Buy Our Drilling & Tapping Spray here: